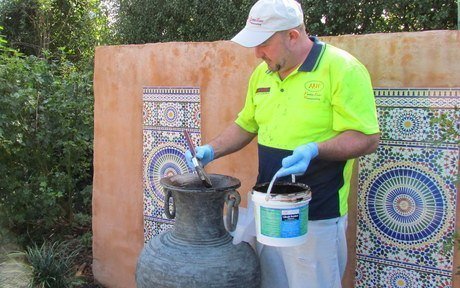

- Liquid Rubber does not require special equipment and being eco-friendly is safe for animals, plants and human drinking water.

- It is easily applied using a brush or roller and typically cures within 24-48 hours (depending on application thickness, temperature, and relative humidity) into a tough rubbery completely waterproof surface.

- Liquid Rubber is also a flexible waterproof membrane meaning it will move with your surface - whether it is a roof, balcony or floor.

- This is an unique property of Liquid Rubber which very few, if any, other membranes offer.

- Changes in temperature and the movement of structures means that it is critical that a membrane can expand and contract - otherwise cracking or peeling occurs.

- Liquid Rubber has excellent adhesion to almost all surfaces and substrates IF APPLIED CORRECTLY.

Liquid Rubber application is just like painting:

- good preparation before applying the waterproof coating gives the best results.

Surface Preparation Before Waterproofing

All surfaces must be prepared correctly before applying waterproofing product : dry and free of anything that could adversely affect the adhesion of Liquid Rubber to the substrate.

- You should be sure to remove all loose, scaling, peeling, blistering, chipping, cracking, chalking or gravel, dust, dirt, sand, soot, grease, oil, uncured tar, wax, soap film, animal fats or petroleum-based residue, coal tar, chlorine, salts, efflorescence, or any other chemically reactive substance (solvents) that may affect adhesion.

- High-pressure water blast or wire brush should be used to thoroughly clean all surfaces prior to application when any of the above conditions exist Surface should be free of all mould, mildew or any other living organism and COMPLETELY DRY.

- Mildew and similar growths need to be killed with 5% chlorine solution household bleach in water, followed by a thorough rinse with clean water.

- All surfaces must then be allowed to THOROUGHLY DRY before proceeding with application.

- After all surfaces are thoroughly dry inspect for cracks, holes and any surface irregularities that will need to be repaired prior to roller/brush Liquid Rubber application.

Waterproofing Needs A Clean Surface

The images below show an existing roof that required remedial waterproofing work. We spent a lot time & effort cleaning and preparing this surface - removing previous membrane and roof dirt.

It doesn't matter what size the job the preparation is always the same - CLEAN & DRY.

Geotextile Bandage

If your surface has joins and/or seams, i.e scyon or cement sheeting, it is recommended that you use the Geotextile Bandage to create a flexible and securely waterproof junction.

The bandage is a non woven fabric designed for use with the Liquid Rubber membrane and high for enhancing reinforcement, tensile strength. The Geotextile bandage is commonly used to provide a waterproof barrier over the construction gap between the internal wall surface and the floor.

The geotextile bandage is supplied as a roll or if you are applying Liquid Rubber to ponds, dams etc.you may need to purchase as a fabric sheet.

The bandage is typically bonded to the wall and floor using the Liquid Rubber as the adhesive: paint on the Liquid Rubber by brush and then lay the Geotextile bandage to the length require, paint Liquid Rubber over the bandage.

This leaves the middle portion of the bandage free to stretch and move relative to the bonded areas.

Curing Times

Typically cures within 24-48 hours (depending on application thickness, temperature, and relative humidity).

You will notice the product is dry to the touch with-in 2-3 hours, however, the rubber is still going through a very important process called “curing”.

This is the process where the rubber becomes one single membrane and can contain water on a continuous basis. This process can take between 5-7 days of warm weather.

If the surface remains damp (like underground concrete) this will greatly extend the curing process.

If “active” water is trying to push through a wet membrane – it will not cure.

Storage & Safety

Liquid Rubber is a non-flammable liquid and does not present any storage or transportation hazards.

Store all Liquid Rubber in a cool dry space over 5°C.

DO NOT ALLOW PRODUCT TO FREEZE

Liquid Rubber will last over 12 months if BUCKET REMAINS TIGHTLY SEALED WHEN NOT IN USE